Different materials are sliced using a laser during the process of laser cutting, which has both practical and creative uses. In this article, other than laser cutting services, we’ve discussed a few other benefits to make the differences between services more prominent.

Such as SendCutSend has waterjet cutting features available, which the OshCut CNC lacks behind. Again OshCut CNC service has flat finishing, which the other doesn’t have. There are some features, too, to check out.

Let’s have a look at them for a better understanding-

A Brief Comparison Table

| Specifications | SendCutSend Service | OshCut CNC Service |

| Laser Cutting | Available | Available |

| Waterjet Cutting | Available | Unavailable |

| Anodizing | Available | Unavailable |

| Flat finishing | Unavailable | Available |

Key Differences Between SendCutSend And OshCut CNC And Laser Cutting Services

- Laser Cutting

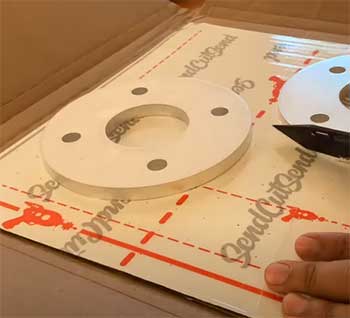

Send Cut Send can cut a wide range of metals, including brass, copper, 304 stainless steel, A36 steel and 6061 aluminium. Most metals can be sliced up to 1/2 inch thick.

In addition to metals, their laser cut services include materials such as Acrylic, Delrin, Cork, Chipboard, and more.

They can produce exact cuts with tight tolerances of +/-.005 inches or better with their fibre laser cutters.

All of your design’s kerf and line offsets are taken into account.

They adjust the beam position according to the part’s geometry and can maintain a +/-.005′′ tolerance or better on most materials.

So that you don’t have to, they take care of everything.

Depending on the material being cut, their fibre laser beam diameter varies between around 0.006″ and 0.010″, but you do not need to change your design to account for the laser cutter’s kerf.

On items with simple geometry, their powerful fibre lasers almost leave no heat-affected zone (HAZ).

Modern fibre lasers can efficiently and quickly cut thin metals at speeds of up to 2,000 inches per minute.

The heat conveyed to the surrounding areas is reduced since they use a narrow beam diameter. Compared to plasma, oxyfuel, and laser thermal cutting, a laser produces the least HAZ while simultaneously being the most accurate and, frequently, the most economical method.

However, OshCut 8 and 10 kW lasers have exceptional cut quality with a little burr, and they can cut through 1″-thick steel, stainless steel, and aluminium.

Heat accumulation substantially impacts cut quality, particularly in thick metals. Their machines use water cooling to keep thick material cold when cutting, and spraying a small amount of oil onto the material while piercing helps reduce splash-out.

On a fibre laser, cutting aluminium neatly is typically challenging. The cut edge will often have constant roughness for anything larger than 1/8″. A fibre laser-cut thick metal plate will have an edge burr up to 1/4″ long.

They virtually eliminated cutting burr on aluminium up to 1″ thick using the most recent cutting technology. The quantity of burr is lower even in a 1″ aluminium plate than a fibre laser would typically leave on a 1/4″ scale.

With +/- 0.005″ accuracy and ultra-high precision, their fibre lasers generate blanks with little to no taper, even in thick plates.

Also Read: Comparison of Trotec And Boss Laser.

- Waterjet Cutting

Waterjet cutting parts has traditionally been a time-consuming and expensive operation for companies and individuals. The pricing would reflect the time constraints if parts had to be found rapidly.

They can offer quick, effective, and reasonably priced waterjet services to everyone, from small enterprises to significant aerospace corporations, because of SendCutSend’s automated waterjet process.

Try their waterjet cutting services if you’re seeking precise cuts in challenging materials like Carbon Fiber, G10, and linen phenolic (Micarta).

Your unique parts will be accurately waterjet cut on carbon fibre, G10/FR4, phenolic (Micarta), and many more materials shortly through their highly automated, customizable technology.

Waterjet cutting is the preferred technique for challenging materials to treat.

Waterjet cutting is superior to laser cutting for composite materials since it doesn’t leave delamination, rough edges, or HAZ.

Due to its high precision cutting capabilities, the waterjet can produce highly detailed cuts in composite materials with tolerances of +-.009″ (.25mm) or better.

There’s virtually no HAZ (heat-affected zone) when your parts are waterjet cut.

When compared to laser cutting, the edge quality produced by waterjet cutting is superior due to the interaction of the water speed, pressure, nozzle size, and abrasive flow rate.

However, OshCut CNC does not have a waterjet cutting in their services added.

- Anodizing

Anodizing is renowned for lengthening the lifespan of parts and enhancing corrosion and wear resistance. The electrochemical method increases durability by adding a surface oxide layer.

Your laser-cut items can get durability and personality by being anodized. The anodizing procedure improves corrosion resistance without covering your product with a substantial material coating.

- Flat Finishing

OSH provides deburring and graining services Cut to enhance surface and edge quality, get rid of burrs, and do away with costly manual processes like grinding.

With a wide belt sander, any burr is removed from the raw laser-cut part edge during the deburring process. Most materials can optionally have a linear grain.

Currently, they deburr with a belt that is 120 grit broad and grain with a belt that is 240 grit wide, yielding a surface finish that is comparable to #4 on stainless steel or aluminium.

Due to typical material handling, raw laser-cut metal typically has minor cosmetic surface scratching. A small amount of bottom burr may also be present on some parts made of certain materials, especially aluminium.

Their finishing machinery gets rid of edge burrs and, if desired, gives the product a linear grain.

The preparation for secondary processes like sandblasting, welding, and painting can frequently be decreased or eliminated with flat finishing.

However, this particular service is unavailable for SendCutSend laser cutting services.

Conclusion

We are at the end of our discussion of the services that the two brands ensure. We have tried to highlight the available, and whatnot features so that you can choose the perfect service for your need.

We hope the article has given you a clear idea with its precise details and added information.

Useful Resource: Differences Between Hypertherm And Thermal Dynamics Plasma Cutter.