The world of adhesives and sealants is a vast one. Amongst numerous options available, epoxy resins have earned a special place due to their versatility, reliability, and strength.

In this article, we focus on two significant players in the epoxy market: Raka and WEST SYSTEM, and we delve deep into their characteristics, pros, cons, and more.

A Brief Comparison Table

| Parameters | Raka Epoxy | WEST SYSTEM Epoxy |

| User-Friendliness | High (simple mixing ratios, long pot life) | Medium (requires understanding of various hardeners and additives) |

| Versatility | Moderate (offers a few hardener options) | High (wide range of hardeners and additives available) |

| Cost | More Affordable | More Expensive |

| Cure Time | Quick Initial Cure (5-6 hours) | Longer Cure Time (Depends on hardener and conditions) |

| Aesthetics | Clear, but can yellow over time | Maintains clarity and color over time |

| Strength & Durability | High, but less than WEST SYSTEM | Very High |

A Closer Look at Raka Epoxy

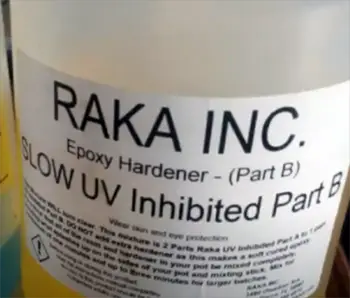

Raka epoxy, often favored by hobbyists and professional builders, is known for its easy-to-use nature and affordable pricing. The resin and hardener system provided by Raka allows you to work with a range of materials, including wood, metal, and fiberglass.

- Key Features and Benefits

Raka epoxy is popular for its user-friendly characteristics.

The mixing ratios are simple, which is excellent for beginners stepping into the world of epoxy.

It offers a long pot life, allowing you ample time to perfect your work.

Another significant benefit is its quick cure time; under the right conditions, Raka epoxy can reach an initial cure within 5-6 hours.

This epoxy system exhibits excellent adhesive properties, binding different surfaces strongly together. The epoxy is also remarkably clear, which makes it ideal for transparent coatings and laminations.

- Potential Drawbacks

While Raka epoxy has several positive attributes, it also has its drawbacks. The consistency is quite thick, which may cause difficulties while working on detailed or intricate designs.

Additionally, it can exhibit a slightly yellowish hue over time, which might affect the aesthetics of the final product.

An Overview of WEST SYSTEM Epoxy

WEST SYSTEM epoxy is another big name in the industry, often the go-to choice for many professionals. It provides a comprehensive range of products designed to cater to diverse requirements.

- Key Features and Benefits

One of the biggest strengths of the WEST SYSTEM is its versatile product range. It offers different hardeners and additives, allowing you to customize the epoxy according to your project needs.

The WEST SYSTEM epoxy provides a high degree of structural strength, making it an ideal choice for heavy-duty applications. Furthermore, it exhibits superior resistance to moisture, chemicals, and heat, ensuring a long-lasting bond.

- Potential Drawbacks

Although the WEST SYSTEM epoxy offers a wide range of products, this could be daunting for beginners due to the complex mixing ratios.

Moreover, it is more expensive compared to other brands, including Raka, which could be a disadvantage for those on a tight budget.

Key Differences Between Raka and WEST SYSTEM Epoxy

When it comes to selecting the right epoxy system for your project, it’s important to consider all the details. So, let’s delve deeper into the key differences between Raka and WEST SYSTEM epoxy.

- User-Friendliness

For a newcomer to the world of epoxy, the simplicity of the Raka epoxy system is a major advantage.

The straightforward mixing ratios offered by Raka – typically 2:1 or 5:1, depending on the specific product – are less confusing for beginners.

The long pot life also allows for a more relaxed pace of work.

On the contrary, WEST SYSTEM epoxy offers a wide array of hardeners and additives, each with different characteristics and mixing ratios. While this provides a higher level of customization, it can be overwhelming for a novice.

- Versatility and Customizability

The extensive product line of WEST SYSTEM epoxy is a big win for those seeking flexibility and customization. You can choose from different hardeners and additives to meet the specific needs of your project, be it faster cure times, increased flexibility, or improved resistance to environmental factors.

Raka, on the other hand, doesn’t provide as extensive a range of customization options. But, it does offer a few hardener options that cater to different temperature and cure time requirements.

- Cost

From a cost perspective, Raka epoxy is typically more affordable than WEST SYSTEM epoxy. This cost-effectiveness makes Raka an attractive option for hobbyists and professionals who have budget constraints.

WEST SYSTEM epoxy, while a bit more expensive, offers value for money considering its versatility and the high-quality finish it delivers.

- Cure Time

Raka epoxy boasts a quick initial cure time, which can be as short as 5-6 hours under optimal conditions. This makes it an excellent choice for projects where speed is of the essence.

WEST SYSTEM epoxy, depending on the hardener and conditions, may have a slightly longer cure time. But it provides a comprehensive cure, resulting in high structural strength and resistance properties.

- Aesthetic Considerations

When it comes to aesthetics, Raka epoxy scores for its clear finish which is ideal for transparent coatings and laminations. However, it can develop a slight yellowish tint over time.

On the other hand, WEST SYSTEM epoxy maintains its clarity and color stability over time, a critical factor for projects where the visual appeal of the finished product is paramount.

- Strength and Durability

Both Raka and WEST SYSTEM epoxy provide strong, durable bonds. However, WEST SYSTEM epoxy is recognized for its high degree of structural strength and resistance to moisture, chemicals, and heat, making it an ideal choice for heavy-duty applications.

Raka epoxy, while not as robust as the WEST SYSTEM, still delivers excellent adhesive properties and binds different surfaces strongly together.

Both Raka and WEST SYSTEM epoxy have their strengths and weaknesses. Raka is affordable, easy to use, and has a quick cure time, while the WEST SYSTEM offers versatility, high strength, and superior resistance. Your choice depends on the specific requirements of your project.

Also Read: Cajun Bass Boat Issues And Problems.

Frequently Asked Questions (FAQ)

Numerous epoxy brands are comparable to the WEST SYSTEM, including MAS Epoxies, System Three, and Raka. These brands also offer high-quality epoxy resins suitable for a range of applications.

The “best” epoxy often depends on your specific needs. If you need versatility and superior strength, WEST SYSTEM is a great choice. On the other hand, if you’re seeking a user-friendly and budget-friendly option, Raka epoxy might be the perfect fit.

Hawk Epoxy and WEST SYSTEM are both high-quality epoxy systems. However, they differ in their product range, mixing ratios, and pricing. Hawk Epoxy is designed to be user-friendly with pre-calibrated pumps, while WEST SYSTEM requires more precise measurements but offers more versatility.

The cure time for Raka epoxy depends on the temperature and the hardener used. Under optimal conditions, it can reach an initial cure in 5-6 hours, but it is recommended to wait at least 24 hours for a full cure.

Final Thoughts

In conclusion, both Raka and WEST SYSTEM epoxies offer great value in their own ways. Your choice should depend on your project’s specific needs, budget, and level of experience with epoxy systems.