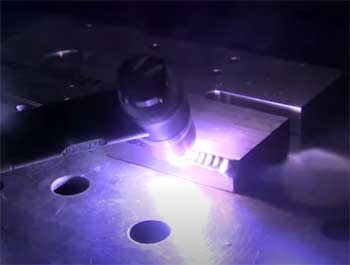

TIG welding machines are all the rage now. But you’ll have to pick a good one like the Lincoln Square Wave 200. And even then you might face problems.

The most common problems with the square wave 200 are electricity conversion issues, overheating, and unsteady welding nozzles.

Even one of the most solid TIG welding machines like the Lincoln square wave 200 can have issues. How bad can they get? Here is a detailed rundown of common Lincoln square wave 200 issues.

Common Issues With Lincoln Square Wave 200 Welding Machine

As good as this welding machine is, there is still room for improvement. But the thing is, most of the common square wave (SW) issues are manufacturing problems. Individual or unit-specific problems happen, but they’re pretty rare.

The room for improvement is pretty big because of this. A bad unit can be replaced, but the manufacturing issues can’t be resolved like that.

The most common issues Lincoln SW 200 users face are electricity conversion problems, machine overheating, and an unsteady welding nozzle.

Let’s see how these issues unfold.

- The Converter Can’t Convert Electricity Properly Sometimes

This is probably the most common issue with Lincoln SW 200 and according to popular verdict, the most annoying one too.

A lot of the time the welding machine either stops or can’t make welding arcs.

This happens because the machine is incapable of supplying the right form of electricity to the computer.

This is something a lot of people notice right off the bat. What happens is that the machine gets running, everything looks good but it can’t make a welding arc.

So it becomes pretty much useless. The fan usually stays running but sometimes it shuts down too.

There can be two reasons for these two happenings. Your electricity flow might be lower than needed or the machine can’t convert them properly.

Every electronic has a fixed amp rating. If your outlet is supplying a lower flow than that, your machine won’t be able to establish a welding arc and work.

Or the converter inside can be the issue. The machine might get the right flow but the converter might fail. In that case, you’ll see similar symptoms.

Another surprising reason can be the helium mix. If the mix has too much helium than is needed, your machine may not have a proper welding arc.

The first thing you can do to solve this problem is to try changing the electric outlet. If you have a different outlet, plug the machine there and see if it works. Make sure that the outlet matches the electricity rating on the manual.

If the machine doesn’t work after you change outlet, you’ll have to go to your nearest repair shop to get this professionally fixed.

Also Read: Problems With Miller Maxstar 161 Welder.

- It Overheats A Lot

This is a cleaning issue. Some Lincoln SW 200 units heat up way beyond the normal range and don’t come down. This can be because of the fan or internal blockage. This is another common issue and might happen right out of the carton.

The SW 200 usually runs a little hotter than other welding machines, but some units are beyond that. They heat up so much that the thermostat turns on, and this happens regularly.

The yellow flash on the front panel is a dead indicator of this issue, the light might blink or just stay on.

The fan does nothing to solve this, it keeps running but it doesn’t cool the machine down.

Usually, the reason behind this is the machine doesn’t have any outlet to recycle the hot air.

If your air ducts are blocked for some reason or have serious dust buildup then that can cause an overheating issue.

Another reason for overheating is the fan getting blocked. If something is stuck near the fan structure and it can’t properly turn, your machine will overheat.

One way of solving this is to clear the air ducts. Blow the dust and debris away with a blowdryer. If that doesn’t work, you’ll need professional help.

- The Welding Nozzle Can Be Unsteady

This is an individual issue. The welding nozzle might not close properly and leave the tungsten unsteady. This makes welding unsafe and of course, imperfect.

The welding nozzle has multiple small parts, you have to set them up to get it going. Sometimes the closing part of the nozzle stays unstable so the tungsten is unstable too. This pretty much makes the whole nozzle non-functional.

This usually happens when the assembly is wrong. Most people start assembling the piece from the front. The right way to assemble this is to start from the back and put the tungsten in at the very last. Then you can pop the back part on and the nozzle will be more stable.

Some units can have faulty nozzles in the first place. In that case, you’ll have to look for a replacement or have a professional mechanic fix it.

Is Lincoln Square Wave 200 Worth It?

For all its issues and problems, the Lincoln SW 200 is still pretty much worth it. This welding machine is steady, portable, and durable too. The user interface is pretty simple which makes it a good starter for beginner-level welders.

But it isn’t just for beginners. The SW 200 can work with a pretty big range of thicknesses so it is good for professionals too.

Unless you’re on the unlucky side and get a bad unit, Lincoln SW 200 is one of the best AC TIG welding machines you’ll see.

Also Read: Miller Dialarc 250 Welder Pros And Cons.

Frequently Asked Questions (FAQ)

Here are a bunch of questions people ask about Lincoln SW 200 and AC TIG welders in general.

Bubbles in TIG welds mean leakage. If your gas cylinder suddenly sustains a leak, your weld will start bubbling.

Yes, Lincoln SW 200 has high frequency start for aluminum.

The best gas for aluminum TIG welding is argon. Helium is a close second, usually, both gases are mixed in a specific ratio.

Argon is the best gas choice for TIG welding mild steel.

Final Verdict

It is better to know what you might walk into before getting a welding machine. So if you’re looking at Lincoln Square Wave 200 problems, this list is a good start.

Make sure to check more customer reviews before getting yourself one and you’ll be fine.