If you’ve ever driven in a noisy car or boat, you know just how unpleasant excessive noise can be. Engine noise, road noise, wind noise – it can give you a headache and make conversations difficult. That’s where sound deadening products come in.

Applying sound deadener to your vehicle’s sheet metal can significantly reduce noise and vibration for a more pleasant ride.

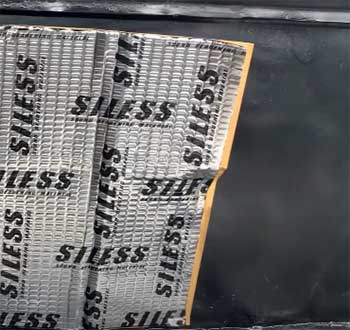

Two of the most popular brands of sound deadening mats are Siless and Noico. But which one is right for your needs? Here we’ll compare the key features and installation of Siless and Noico to help you choose the best sound deadener for your car, truck, boat, RV, or other vehicle.

A Brief Comparison Table

| Feature | Siless | Noico |

| Materials | Bitumen + Butyl Rubber | Butyl Rubber |

| Temperature Resistance | -40°F to 176°F | -40°F to 203°F |

| Sheet Sizing | Large sheets | More pre-cut kits |

| Adhesive Strength | Strong | Very Strong |

| Noise Reduction | Excellent | Excellent |

| Price | $$ | $$$ |

| Ease of Installation | Easy DIY | Easy DIY, more pre-cuts |

| Availability | Good | Good |

What Is Sound Deadening And How Does It Work?

Before we dive into the Siless vs Noico comparison, let’s quickly cover what sound deadening is and how it works to block noise.

Sound deadening products are made from thin, flexible mats of butyl rubber, asphalt, or other noise dampening materials. When applied to vehicle sheet metal, these mats add mass and damping which reduces noise and vibration in two key ways:

- Blocking Noise: The dense mats reflect soundwaves rather than letting them pass through, preventing exterior noise from entering the cabin.

- Damping Vibrations: The mats absorb vibrations from the sheet metal panels, preventing those panels from vibrating and amplifying noise.

This noise blocking and vibration damping creates a quieter interior so you can better enjoy the ride. Now let’s see how Siless and Noico deadeners stack up.

Siless Sound Deadener Overview

Siless is a popular automotive sound deadening brand from Latvia that uses a bitumen and butyl rubber-based formula. Here are the key details on Siless dampening mats:

- Comes in sheets or rolls in various sizes

- Features aluminum coating on mat for heat resistance

- Rated for temps between -40°F to 176°F (-40°C to 80°C)

- Easy to cut and mold around curved surfaces

- Sticks well to sheet metal and holds form over time

- 1/8 inch (3mm) thick medium density mat

The combination of bitumen, butyl, and aluminum allows Siless mats to effectively reflect noise and absorb vibrations across a wide temperature range. The mats are pliable for shaping yet firm enough to hold their form once installed.

Many auto enthusiasts swear by Siless brand sound deadener and use it to successfully reduce noise in cars, trucks, SUVs, vans, boats, RVs, tractors and more.

It’s an affordable dampening option that delivers noticeable noise reduction.

Noico Sound Deadener Overview

Noico is another top contender in the automotive sound dampening market. This brand from Russia utilizes a butyl rubber and aluminum coated formula for its noise insulating mats. Here are the key specs on Noico deadener:

- Sold in sheets or pre-cut kits for specific vehicles

- Features an aluminum backing for heat resistance

- Rated for temps from -40°F to 203°F (-40°C to 95°C)

- Firm 1/8 inch (3mm) thick mat holds shape well

- Moldable to conform around curved surfaces

- Strong adhesive backing sticks securely to sheet metal

The combination of butyl rubber and aluminum gives Noico mats the ability to effectively dampen noise and vibrations across a wide temp range.

The mats are pliable yet firm enough to hold shape once applied.

Many auto enthusiasts use Noico brand sound deadener kits to successfully reduce noise in their vehicles.

It provides noticeable noise and vibration reduction at an affordable price point.

Now that we’ve covered the basics on each brand, let’s compare them head-to-head.

Siless And Noico Sound Deadeners: Key Comparison Points

While Siless and Noico share similarities, there are some key differences between the two brands:

- Materials: Siless uses a bitumen and butyl rubber formula, while Noico relies solely on butyl rubber. Both enhance vibration damping.

- Temperature Resistance: Noico deadener is rated for slightly higher temps, at -40° to 203°F vs. Siless’ rating of -40° to 176°F. Both work well across a wide temp range.

- Sheet Sizing: Siless offers its sound deadener in larger sheet sizes, while Noico has more pre-cut vehicle-specific kits.

- Adhesive Strength: Both feature a strong adhesive backing to securely bond mats to sheet metal. Noico’s adhesive may have a slightly stronger hold.

- Noise Reduction: Independent tests show Siless and Noico provide comparable noise reduction levels when properly installed.

- Price: Siless is generally a little more affordable than Noico brand sound deadener. But both offer good value.

- Ease of Installation: The two brands have similar pliability and are equally easy to install DIY. Noico does offer more pre-cut kits requiring less shaping.

Both Siless and Noico deliver on the two most important metrics – effectively reducing noise and vibration. While their materials and sizing differ slightly, real world noise dampening performance should be similar if products are installed correctly.

So which brand is right for your vehicle? We’ll dig into that next.

Choosing The Best Sound Deadener: Siless Or Noico?

With comparable noise reducing performance, choosing between Siless and Noico comes down to your specific vehicle, project scope, and budget. Here are some factors to help determine which deadener is the best fit:

- Vehicle Size: For larger vehicles, Siless’ wider sheets can cover more area efficiently. For smaller projects, Noico’s pre-cut kits may work better.

- Installation DIY vs Pro: DIYers may appreciate Siless’ larger sheets for custom jobs. Noico’s vehicle-specific kits require less shaping for beginners. Pros can work efficiently with either brand.

- Budget: If sticking to a strict budget, Siless is the more affordable option that still delivers quieting performance. Noico works well if you have extra funds to invest.

- Climate: For extreme cold or hot climates, Noico’s slightly wider temperature tolerance may give it an edge. Both brands effectively dampen across a wide range.

- Project Scope: Using both brands together provides enhanced noise reduction. Layer Noico over Siless for maximum sound deadening.

- Availability: Check vendor availability for the brand you select to ensure you can get the necessary sheets or kits when needed.

As you can see, there are good arguments to be made for either brand depending on your specific vehicle and needs. Combining Siless and Noico can provide enhanced noise dampening for critical applications like sound studios.

For most DIY vehicle projects, you can achieve noticeable noise reduction with either brand on its own.

How To Install Siless and Noico Sound Deadener?

Whichever brand you choose, proper installation is key to getting the full noise dampening benefits. Here is a quick overview of sound deadener installation best practices:

- Thoroughly clean all sheet metal surfaces before application. Remove any oil, grease, or dirt so the mats adhere tightly.

- Focus application on large, flat exterior panels first as these amplify the most noise. Common areas include doors, rear hatch, roof, trunk, undercarriage, hood, etc.

- Cut mats to fit each section. Remove backing and press firmly to activate adhesive and bond mat to metal.

- For curved panels, use a heat gun to warm mats and increase pliability before shaping to contours.

- Press all seams firmly to create a tight bond and prevent gaps where noise can enter.

- Work methodically and apply even pressure across all mat surfaces to create a strong bond to sheet metal.

- Use a roller tool to apply additional pressure and improve adhesion after application.

- Seal all seams and edges with additional butyl rope caulk to prevent gaps and create a noise-blocking barrier.

With proper preparation and installation, both Siless and Noico provide excellent noise dampening and vibration absorption within a vehicle cabin. Enhanced comfort and audio clarity are just a few benefits of upgrading your ride with sound deadener.

Also Read: Is MAT66 Better Than Kilmat Sound Deadener?

Sound Deadening FAQ

Still have some questions about sound dampening products and choosing the right brand for your vehicle? Here are answers to some frequently asked questions:

For most applications, Siless and Noico deliver comparable noise dampening performance. Both utilize formulas proven to effectively reduce noise and vibrations. There is no universally agreed “best” sound deadener brand. Choose based on your vehicle, climate, budget and project goals.

Siless and Noico are two of the top-rated car damping sheet brands, providing noticeable noise reduction. For DIY installs, Siless’ wider sheets may work a bit better to cover large exterior panels. Noico also dampens extremely well and has more pre-cut kits available.

Both Siless and Noico make excellent car noise insulation mats to significantly reduce road noise, wind noise and engine noise. Layering both brands can provide enhanced noise blocking for the ultimate quiet ride. Proper coverage of exterior sheet metal is key for good insulation.

Marine environments are demanding, but Siless and Noico deadeners stand up well to moisture and vibration. For steel-hulled boats, Noico’s strong adhesive may give it an edge. Fiberglass hulls will require extra adhesion promoters before applying either brand. Covering the entire hull is ideal for maximum noise and vibration damping.

Achieving a Quieter Ride

Upgrading your car, truck, boat, RV or other vehicle with Siless or Noico sound deadener is an affordable way to significantly reduce unwanted noise and vibration. With comparable noise dampening abilities, choosing between the two brands comes down to your specific project needs and budget.

Either option provides noticeable sound blocking when properly installed.

For most applications, start with 25% coverage of exterior sheet metal and critical panels to appreciably reduce noise. Going up to 50-100% coverage provides even more sound dampening for the ultimate quiet ride.

Combined with audio upgrades, sound deadening creates a premium listening environment so you can fully enjoy the journey.