There’s something almost magical about an adhesive that sticks like a shadow, no matter the conditions. It holds things together, quite literally. But when it comes to picking the right one, it’s not as simple as one might think.

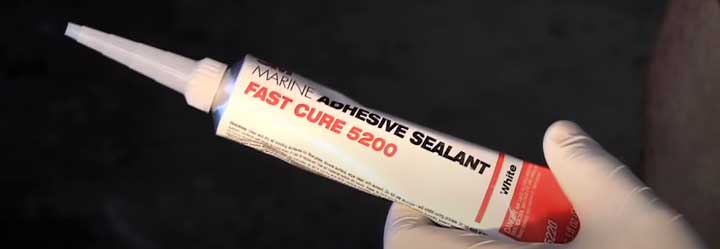

Especially when the options are as formidable as the 3M 5200 Fast Cure and the Regular Adhesive. Both are marine-grade sealants produced by 3M, a world-renowned multinational conglomerate known for their innovative products.

A Comprehensive Comparison Table

| Feature | 3M 5200 Fast Cure | Regular 3M 5200 |

| Curing Time | 24 hours for initial set, ~48 hours for 90% cure | Up to 7 days for full cure |

| Working Time | Short | Long |

| Underwater Curing | Yes | No |

| Bonding Strength | High | Higher |

| Best for | Projects needing quick curing, underwater applications | Heavy-duty applications, projects that allow more adjustment time |

| Trade-offs | Lower strength, less adjustment time | Longer curing time, no underwater curing |

3M 5200 Fast Cure – Built for Speed

In our fast-paced world, waiting around isn’t always an option. That’s where the 3M 5200 Fast Cure earns its stripes. This adhesive provides all the bonding strength of its regular counterpart, but with a swift cure time that makes it perfect for projects with tight deadlines.

- Pros of 3M 5200 Fast Cure

One of the key benefits of the Fast Cure is, as you’ve probably guessed, its speed. While regular adhesives take up to a week to fully cure, the Fast Cure version sets in just 24 hours, and reaches approximately 90% of its final cure within 48 hours.

This short cure time means it’s ready to withstand the pressures of the marine environment much sooner than the regular adhesive.

The Fast Cure also excels in underwater curing. Yes, you read it right. This stuff can cure even underwater, which can be a lifesaver in situations where draining or dry-docking just isn’t an option.

- Cons of 3M 5200 Fast Cure

The Fast Cure isn’t without its drawbacks. Its quick set time can be a double-edged sword. If your project requires more time for adjustment or repositioning, the rapid curing might prove problematic.

Another downside is that it may not be the best choice for applications requiring maximum bonding strength, such as heavy-duty structural bonding. While it’s still impressively strong, the regular 3M 5200 provides slightly better strength due to its longer curing process.

Also Read: Differences Between Loctite PL Marine And 3M 4200 Marine Adhesives.

Regular 3M 5200 – Slow and Steady

While the Fast Cure thrives on its swift set time, the Regular 3M 5200 adhesive plays the long game, but in the end, it provides an unbeatable level of bonding strength.

- Pros of Regular 3M 5200

The most significant advantage of the regular 3M 5200 adhesive is its bonding strength.

Its slower cure time means the adhesive forms a stronger, more solid bond that’s better suited to heavy-duty applications.

The regular 3M 5200 also provides a more extended work time.

This extra time to manipulate and adjust ensures that you get your project set up just right before the adhesive starts to set.

- Cons of Regular 3M 5200

The slower cure time of the regular adhesive can be inconvenient if you’re working under a tight schedule. While the strength of the bond is higher, it takes up to a week to fully cure.

Also, unlike the Fast Cure, the Regular 3M 5200 doesn’t cure underwater. This could be a significant disadvantage if you’re dealing with an underwater application.

Key Differences Between 3M 5200 Fast Cure and Regular Adhesive

Both the 3M 5200 Fast Cure and the Regular Adhesive stand tall as excellent marine-grade adhesives, but they each have their unique selling points. Let’s dive deeper into their key differences.

- Curing Time

The most significant difference between the two adhesives is the curing time.

Fast Cure: As the name implies, the Fast Cure is built for speed. It sets within 24 hours and reaches approximately 90% of its final cure within 48 hours. This quick curing time is particularly beneficial in situations where you don’t have the luxury of waiting for a full week before moving on to the next stage of your project.

Regular Adhesive: On the other hand, the Regular 3M 5200 adhesive takes its sweet time to cure. It provides a full week for the curing process, which contributes to the creation of a stronger bond.

While this slow pace may seem like a disadvantage, it can actually be beneficial for certain applications that require a higher bonding strength, and when you have the time to wait for it to fully cure.

- Working Time

Working time, or the time you have to adjust the adhesive before it starts to set, also differs between these two products.

Fast Cure: Due to its rapid curing property, the Fast Cure gives a limited time for adjustments. This quick-setting feature makes it suitable for projects where immediate adhesion is needed, but it may prove challenging if your task requires fine adjustments or repositioning after applying the adhesive.

Regular Adhesive: The regular adhesive offers a longer working time, which is perfect for tasks that require a bit more finesse and adjustment after applying the adhesive. This feature provides a more forgiving workspace and reduces the stress of having to get everything right immediately.

- Underwater Curing

Whether an adhesive can cure underwater or not is a critical consideration for marine applications. Here again, the 3M 5200 Fast Cure and Regular Adhesive differ.

Fast Cure: This adhesive is a game-changer when it comes to underwater applications. The Fast Cure’s unique ability to cure underwater makes it an excellent choice for repairs where it’s impossible or impractical to dry the area completely.

This property extends its usage to a wide range of marine applications, which can be a real lifesaver in certain scenarios.

Regular Adhesive: Unfortunately, the Regular 3M 5200 adhesive doesn’t possess the underwater curing ability of its faster counterpart. While it’s still a highly effective adhesive, its inability to cure underwater could limit its usage in certain marine applications where water exposure is unavoidable.

- Bonding Strength

Finally, the bonding strength of the two adhesives varies due to their different curing times.

Fast Cure: Although it’s still incredibly strong, the Fast Cure does have a slightly lower bonding strength than the regular version due to its quick curing process.

Regular Adhesive: The regular version, with its extended curing time, delivers a stronger bond, making it the better choice for heavy-duty applications that require the maximum possible bonding strength.

Also Read: How 3M 4200 Is Differant Than 5200 Marine Adhesive?

Frequently Asked Questions (FAQ)

3M 5200 Fast Cure is designed to set in just 24 hours, with around 90% of its final cure reached within 48 hours.

Increasing the temperature and humidity can help the 5200 cure faster. But remember, speeding up the curing process may decrease the overall bonding strength.

3M 5200 cures at typical room temperatures of 70-80 degrees Fahrenheit. However, the curing process may take longer at cooler temperatures.

Yes, one of the standout features of 5200 Fast Cure is its ability to cure underwater.

Final Words

Choosing between 3M 5200 Fast Cure and Regular Adhesive boils down to your specific needs. If speed is crucial, the Fast Cure will serve you well. But if you’re aiming for maximum strength and have the luxury of time, the Regular Adhesive wins the day.

Both are strong contenders, quite literally, and offer excellent durability, making them solid choices for your marine applications.