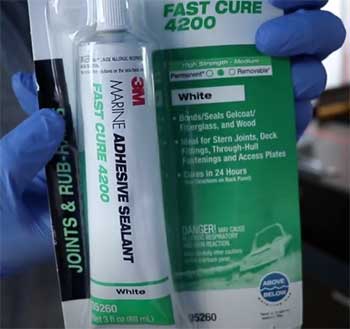

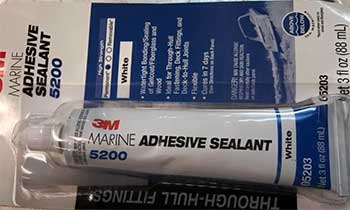

3M 4200 or 5200 adhesive sealants are widely used by boaters when they have to make a firm connection between different parts of their boats.

However, both have their significant differences. The 4200 sealants are highly recommended to use at places where you need a quick recovery and easy dissembling shortly.

On the other hand, the 5000 polyurethane is used where you need a permanent recovery and is often stronger than 4200. You’ll know more differences between these sealants in this guide.

A Quick Comparison Table

| Credentials | 3M 4200 Adhesive Sealant | 3M 5200 Adhesive Sealant |

| Brand | 3M | 3M |

| Case Of Application | Best to use where fast recovery is required, and letter dissembling of parts is needed | Extremely hard to remove and used as a permanent solution to join parts |

| Durability | Less Durable | Extremely Durable |

| Removability | Easy To Remove after a certain period | Difficult to remove even after a certain period |

| Salt Water Usage | Yes, it can be used above and below the saltwater | It can also be used above and below the saltwater |

| Curing Time | 15-30 minutes | Tack-free in 24-48 hours; |

| Shore A Hardness | 40 | 68 |

| Tensile Strength PSI | 500 | 700 |

| Color Options | Only available in white color | Available in a variety of colors |

Key Differences Between The 3M 4200 And 5200 Marine Adhesive Sealants

- Brand

The main similarity between these two sealants is that they belong to the same brand, 3M.

They are considered the toughest sealants on the sea, providing quick connectivity, excellent durability, and strong protection for your boat parts.

Besides, these sealants also protect against moisture. It doesn’t matter what type of hardware you install on your boat; using either will be beneficial.

But 4200 UV is often used where you need quick recovery and is highly recommended if you want to replace your parts later on.

And 5200 is used where you want to ensure a permanent connection.

Also Read: Alternatives To Adhesive 847.

- Case of Application

Both adhesive sealants work in their area of application. Using the 4200 adhesives to join parts means you will be easier and more comfortable removing that hardware after 5 years of usage.

It is a very high-performing and color-stable adhesive sealant that is much easier to remove when you need to rework your boat or repair something.

On the other hand, when you plan never to remove those hardware parts in the future, using 5200 adhesives is recommended.

In most cases, your joined parts will structurally fail before this adhesive does, and there will be nothing you can do about it.

- Durability

From the application point of view, it is clear that the 4200 adhesive sealant doesn’t provide that durability level as the 5200. Because sooner or later, you can remove 4200. However, it won’t happen with the 5200.

4200 adhesive Sealant is often ideal for those deck hardware solutions where you need to do thru-hull fittings.

It works fine on the above or below side of the water where you need a durable seal and cosmetics.

Compared to 4200, 5200 sealants are something more and are currently considered one of the strongest and high-performing polyurethane.

It does work above and below the water by creating some strongest and non-removable bonds.

- Removability

Either adhesive will give you a strong bond if you want it for longer. However, even if you have used 4200 sealants for almost 5 years and there is a need to remove those parts.

Or disassemble the hardware you have installed on your boats; it is easily removable. But that’s not the case with 5200 sealants.

It provides excellent resistance, and even that material may break or bend down. Still, this adhesive will not come out easily. It is used where maintaining longer productivity is crucial.

- Salt Water Usage

The biggest advantage of 5200 sealants over 4200 is that it is a masterpiece to use under salt water.

Because there, it provides the strongest resistance without complaining to you about any parts leakages on your boat.

But there is also no problem with using 4200 sealants above or below the salt water. It can also stand well in most crucial cases.

Just in case you have more parts working under the water and don’t want any trouble with their functionality, using the 5200 adhesives is always the best option.

- Curing Time

It is a period a specific adhesive takes to dry when it is applied on a certain surface. Usually, working with the 4200 option will provide you with the fastest curing within 15 to 30 minutes. It means you can use this sealant where you need fast recovery.

However, 5200 sealants will ultimately require more time to heal those joined parts. It can usually take more than 48 hours when you use it to join different parts together.

- Shore A Hardness

With 4200 adhesive sealants, you will find a hardness level of up to 40 ASTM C661. But 5200 sealant gives you a hardness level of 68 ASTM C661, which is more than 4200.

This states that 5200 adhesive sealants provide more hardness when applied than 4200 sealants.

- Tensile Strength PSI

The ability for a certain adhesive to bend or provide tensile when it is used on a specific material. Usually, things are easy to bend with 4200 sealants because it has a tensile strength of 500 ASTM D412.

On the other hand, bending things like stanchions, clutches, hinges, and other stuff with the 5200 adhesives is a little difficult because it gives a tensile strength of 700 ASTM D412.

- Color Options

People don’t usually rely on the types of colors available with either of these adhesives as they are more concerned about durability and quality.

But still, 5200 sealant comes with more color options than 4200 as there is only white Colour with the latter option.

Which Marine Adhesive Sealant Is Better For You?

The usage of any of these adhesives will be dependent on the situation you are facing with your boat. If you want that installed hardware on your boat to work for longer, consider using the 5200 adhesive sealants.

However, if you are making it through the hard times and have a plan for later removal or repair of those joints, you can use 4200 adhesive sealants.

But I think going with 4200 is always better because it leaves an option for improvement even after 10 years of usage. Watch, how fast it can cure too!

Also Read: Differences Between Sikaflex 715 And Dicor.

Frequently Asked Questions (FAQ)

You can use this adhesive even below the waterlines without any problem. But going with 5200 will be better.

It is a good adhesive to use when you need to dissemble those parts later on and look for faster recovery when an adhesive is applied on joints.

It takes up to 15 to 30 minutes for 4200 to cure.

Not that matching comparison, but PL S40 can be compared with 3M 5200 to some extent. The former has an even slower curing time.

Final Thoughts

Finally, concluding the comparison between 3M 4200 vs. 5200 depends on the specific situation in which you will consider using either of these adhesives. You can go with the 5200 adhesives if you need long-time connectivity, more hardness, durability, and excellent joining for parts under or above the waterline.

But going with 4200 is also not bad as it provides faster curing with the latter dissembling of those joined parts.