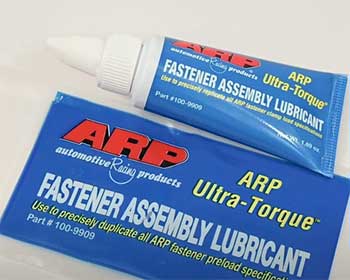

ARP Ultra-Torque fastener lubricant has been a go-to product for many engine builders and racers for years. This sticky liquid reduces friction andprovides an extra layer of protection between critical fasteners and machined surfaces.

However, ARP lube can be difficult to find and expensive when you do track it down. Are there any suitable alternatives that offer the same benefits without the hassle or cost?

I’ve researched and tested several ARP Ultra-Torque lube alternatives that provide comparable friction and corrosion resistance. In this guide, I’ll overview the top options with pros, cons, and recommendations to help you choose the right ARP lube substitute for your engine build or repair project.

Do You Have To Use ARP Lube?

Using some type of lubricant on ARP fasteners is highly recommended for optimal performance and longevity. ARP’s specially formulated lube provides the right blend of friction reduction, anti-seize, and anti-corrosion properties.

You don’t necessarily have to use the ARP branded lubricant, but whatever you use in its place should replicate those key features. An inferior lube alternative may lead to inconsistent clamping force, fastener wear, galling, or seizure.

So while ARP Ultra-Torque is not mandatory, choosing a high-quality equivalent lube is advised. The alternatives below can substitute well when authentic ARP lubricant is inconvenient to obtain or too costly.

What Is ARP Ultra-Torque?

Before reviewing alternatives, it helps to understand what makes ARP Ultra-Torque unique.

This lubricant was designed specifically for use with ARP fasteners in high-stress environments.

The sticky compound utilizes molybdenum disulfide (also called moly) as its main friction modifier.

Moly bonds to the fastener and mating surfaces to prevent metal-on-metal contact and galling.

It also provides protection from rust and corrosion.

Ultra-Torque has a high shear strength to cling tenaciously to bolt threads and surfaces. And it has the high-temp stability required for racing applications. This performance-optimized formula provides the right lubrication for ARP hardware in critical systems.

Alternatives To ARP Ultra-Torque Lube

Here is a list of its equivalents:

- Motor Assembly Lube

- Anti-Seize Lubricant

- Moly Paste

- Graphite Powder

- Nickel Anti-Seize

- Ceramic Paste

- Moly Oil

- White Lithium Grease

Let’s talk about them in detail

Motor Assembly Lube

One of the most common and readily available alternatives is standard motor assembly lube.

This petroleum-based lubricant contains moly for reduced friction and corrosion protection.

Leading brands like Royal Purple and Lucas Oil make well-regarded motor assembly greases.

Pros:

- Readily available at auto parts stores and online retailers

- Cost-effective

- Contains moly for friction reduction

- Already used by many engine builders

Cons:

- Not specifically formulated for ARP fasteners

- Lower shear strength than ARP lube

- Requires reapplication after disassembly

Overall, standard assembly lube works well as an affordable and accessible alternative. Just be sure to apply a liberal amount to threads and contact areas. It may require reapplication if the fasteners are removed.

Anti-Seize Lubricant

Another option is a high-quality anti-seize lubricant, like those made by Permatex and Loctite. These contain moly or copper particles to prevent galling and seizure between threads. Name brands are usually temperature resistant as well.

Pros:

- Widely available and affordable

- Contains anti-seize additives like moly or copper

- Sticks well to threads and surfaces

- Handles high temps

Cons:

- Not specifically designed for ARP fasteners

- Lower shear strength than ARP lube

Anti-seize is an easy ARP lube alternative to use. Just apply it thoroughly on the threads and contact surfaces. Reapplication may be needed after disassembly. Anti-seize spray is the easiest to apply.

Moly Paste

For a barebones moly-based lubricant, you can use moly paste or grease. These thick formulations are pure molybdenum disulfide in a carrier base. Common brand names include Molykote and Dow Corning.

Pros:

- Pure moly for reduced friction

- Thick consistency stays put on threads

- Inexpensive and versatile

- Can handle high temps

Cons:

- No anti-seize or anti-corrosion additives

- Requires frequent reapplication

- Can be messy

Moly paste is an affordable and easily-sourced ARP lube alternative.

Just know it lacks the corrosion protection and shear strength of purpose-built formulations. Frequent reapplication will be needed.

Graphite Powder

Dry graphite powder can work well as a substitute for ARP lube. The graphite coats the threads and surfaces to reduce friction and galling. Leading brands like Asbury and Dixon sell industrial graphite powder.

Pros:

- Slippery graphite minimizes friction

- Inexpensive and easy to apply

- Can be used in place of moly

Cons:

- Can be messy

- No anti-seize properties

- Offers minimal corrosion protection

- Requires very frequent reapplication

Graphite powder lacks some features of ARP lube but provides low-friction lubrication. Just know it will easily wipe off and needs heavy reapplication. Overall an affordable temporary solution.

Nickel Anti-Seize

Nickel anti-seize lubricants are a step above regular anti-seize, thanks to nickel flakes in the grease. The nickel provides superior lubrication and galling resistance compared to copper or other particles. Brands like Loctite and Henkel make nickel anti-seize products.

Pros:

- Excellent anti-seize properties from nickel filler

- High torque reduction on fasteners

- Sticks well to surfaces

- Withstands high temps

Cons:

- More expensive than regular anti-seize

- Not specifically for ARP fasteners

- Lower shear strength than ARP lube

Nickel anti-seize is a premium option if you need maximum galling resistance and reduced friction. The cost is higher but it performs better than basic anti-seize.

Ceramic Paste

Ceramic-infused greases offer another advanced ARP lube alternative. Microscopic ceramic particles provide extreme slipperiness while minimizing metal contact. Brands include Anti-Seize Technology and Jet-Lube.

Pros:

- Outstanding lubrication from ceramic particles

- Prevents galling and metal transfer

- Stays put on surfaces nicely

- Handles high temps

Cons:

- Costlier than typical lubes

- Not formulated for ARP hardware

The premium lubrication of ceramic paste makes it ideal for critical engine fasteners. Despite the higher cost, it prevents galling better than most alternatives.

Moly Oil

Moly-fortified engine oil and gear oil provide another option for ARP lubrication. The moly additive provides wear protection, reduced friction, and extreme pressure performance.

Pros:

- Contains moly for slipperiness

- Adds extra wear protection

- Improves high load capacity

- Easy to apply

Cons:

- Offers minimal corrosion protection

- Requires very frequent re-application

While not a heavy-duty paste, moly oil does give friction reduction and extreme pressure lubrication.

Just be prepared for short-lived protection that needs frequent renewal.

White Lithium Grease

A final option is white lithium grease, like Super Lube or LubriMatic brands. The thick lubricant contains lithium soap to hold onto surfaces tenaciously.

Pros:

- Stays put well on threads and surfaces

- Resists water washout

- Lubricates effectively

- Affordable and easily found

Cons:

- No moly or other friction modifiers

- Limited corrosion protection

- Requires reapplication after disassembly

While not as optimized as ARP lube, white lithium is a viable alternative for the budget-minded. Just be diligent about proper application and reapplying if needed.

Also Read: Crossbow Rail Lube Equivalents.

Frequently Asked Questions (FAQ)

No, you don’t have to use ARP branded lube. However, you should use some type of equivalent high-performance lubricant on ARP fasteners for proper clamping force, durability, and corrosion resistance.

ARP Ultra-Torque is a proprietary thread lubricant formulated specifically for use with ARP fasteners. It contains molybdenum disulfide for friction reduction and has a tenacious consistency that adheres well to surfaces. This optimized formula prevents galling and protects against rust.

Motor assembly lube likely provides the closest performance to ARP Ultra-Torque. It contains moly for friction modification and minimizes corrosion. Assembly lube designed for engines has properties ideal for ARP fastener lubrication. Anti-seize, moly grease, white lithium, and graphite powder can also substitute well.

Using the right ARP fastener lubricant alternative provides similar friction, anti-seize, and protection properties. Just avoid inferior lubricants – spend a few extra bucks to get an optimal ARP lube substitute. Taking the time to properly lubricate hardware is cheap engine insurance.

Closing Remarks

Out of these alternatives, the motor assembly lube likely provides the closest performance to genuine ARP Ultra-Torque. It contains moly for friction reduction and minimizes galling and corrosion. Standard assembly grease is also affordable and readily available.

Anti-seize and moly paste are two other good options depending on your needs. White lithium grease and graphite powder work in a pinch but fall short of the ideal properties.

No matter which alternative you choose, apply it thoroughly to all threads and contact surfaces. And don’t skimp on the amount – more is better for proper lubrication. Taking these steps will provide reliable lubrication very close to Ultra-Torque performance.